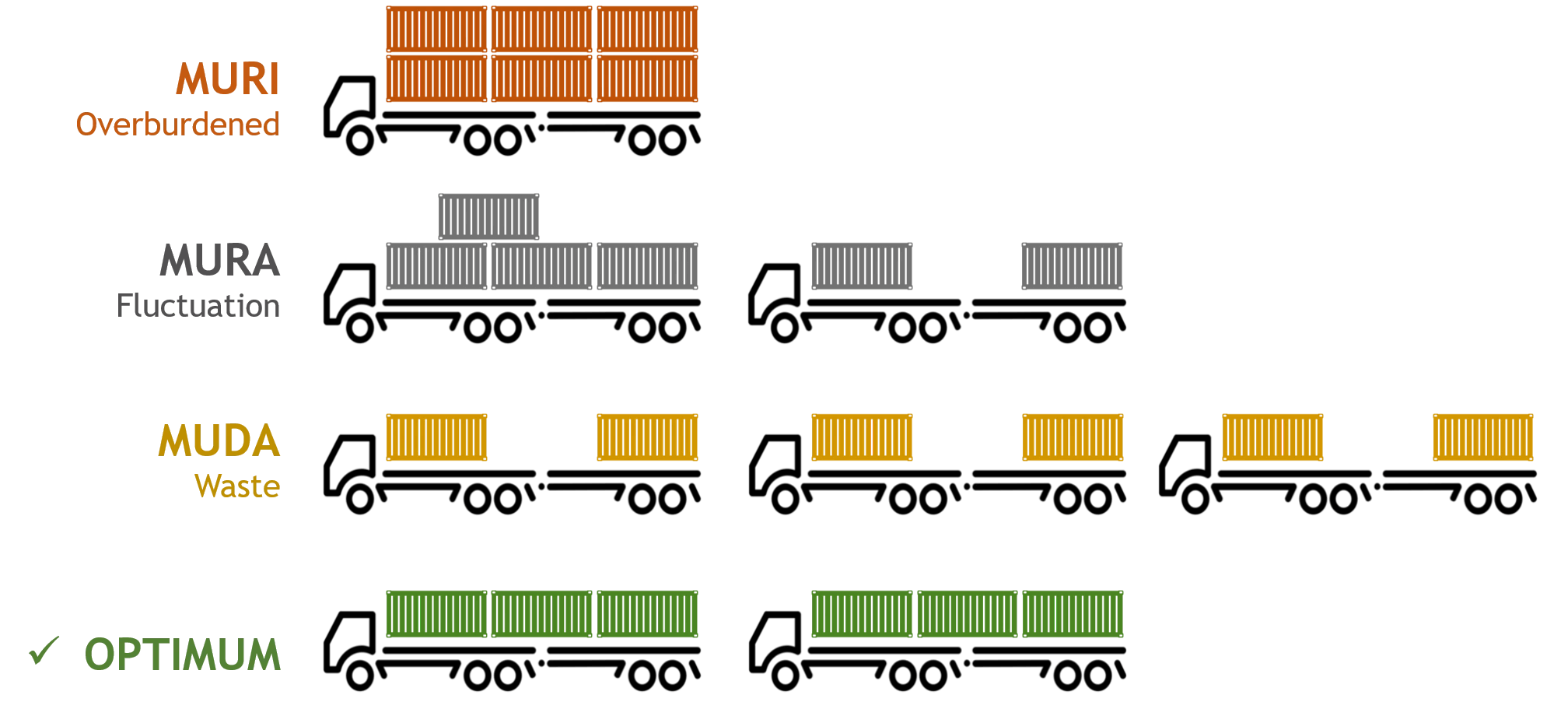

3 BASIC WASTE SOURCE: MURI, MURA, MUDA

All activities and situations that led to waste in the system, away from the best production system, are classified as MURI, MURA and MURI. Although it is generally known as “wastage’’; Muri and Mura are not seen, but can be reached by examining the detailed sources of waste.

MURI

Overburdened

MURI means overloading on all factors that add value to production. An example of MURI is to load a person over their natural boundaries and cause more work than a machine can do.

MURA

Fluctuation

MURA means unbalanced work load (missing-loaded capacity utilization) to value-adding factors such as machinery and human. This irregularity can be caused by production program errors, time loss or missing-defective component factors.

MUDA

Waste

MUDA is all activities and situations that increase the cycle time of any job and are used more than the needs. Activities that increase the cycle time of a line; time spent taking any material or tool, activities extending from the non-ergonomic workstations, disruptions caused by walking are examples of MUDA.

7 CAUSES OF MUDA

Excess Production (faster than customer demand, advance and over production)

Excess Stock (Raw material, semi-finished and finished product stock does not add value to production)

Delays (Unstable operation times between stations)

Walking (Time spent to get any material or tool)

Transports (unnecessary transport of semi-finished products)

Reprocessed Materials (Repetitive operations due to manufacturing defects)

Overprocessing (Operating process more than customer wants)