The URT-V2 Wireless Data Collection Device receives information such as production number, machine operation / stop / failure status and energy consumption / temperature / vibration / density of the machines independently from the sensors on the machine.

Operators can easily enter production data on the device. Data received from machines and operators are transmitted to the central receiving terminal via a wireless system.

With URT-V2 Wireless Data Collection Terminals, there is no need to use hardware such as tablets, kiosks, industrial PCs in data collection scenario. While these terminals collect data from the machines, operators enter production data into the terminals.

- Operating Voltage Range: DC 7-35 Volts

- Number of Channels: 125

- Frequency Band: 2.4 GHz ISM Band

- Display: 4x20 characters, LCD

- Barcode Reader Support

- Octal Selection Function Keys

- Analog and Digital Input-Outputs

- Data exchange via PLC and RS232

- Automatic Stop Detection and Termination

- Machine Control with Relay

- Communication of All Functions with Database

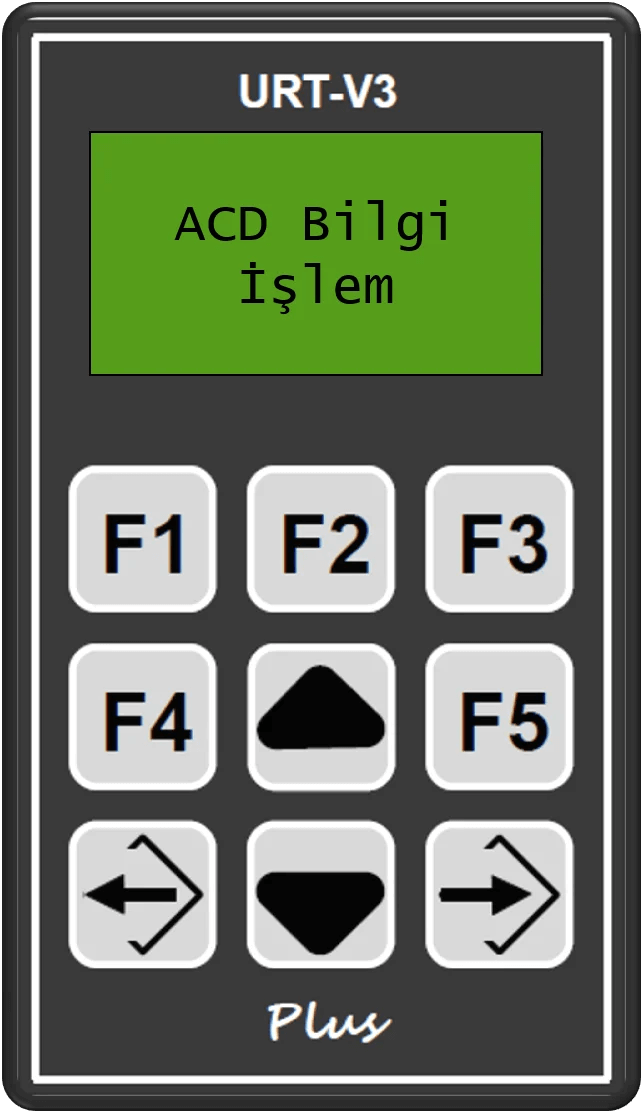

The URT-V3 Wireless Data Collection Device receives information such as production number, machine operation / stop / failure status and energy consumption / temperature / vibration / density of the machines independently from the sensors on the machine. The data received from the machines are transmitted to the central receiving terminal via a wireless system.

In the data collection scenario with URT-V2 Wireless Data Collection Terminals, operators enter their production data into the web-based ACD IPM Data Entry and Monitoring Module running on tablets, kiosks, industrial PCs.

- Operating Voltage Range: DC 7-35 Volts

- Number of Channels: 125

- Frequency Band: 2.4 GHz ISM Band

- Display: OLED LCD

- Barcode Reader Support

- Quintuple Selection Function Keys

- Analog and Digital Input-Outputs

- Data exchange via PLC and RS232

- Automatic Stop Detection and Termination

- Machine Control with Relay

- Communication of All Functions with Database

Central Receiver Terminal receives the RF signals from the URT-V2 Plus and URT-V3 Plus data collection devices and transmits them to the server.

No data loss or interference with other frequencies occurs during data exchange.

According to facility capacity more than central receiver can be integrated to the system.

WHEN WIRELESS DATA COLLECTION DEVICES ARE USED

- Machine-line location changes are not a problem.

- Risks arising from wiring do not occur.

- No time is wasted with wiring.

- Cabling cost is eliminated.

- The system is commissioned faster.