Shift Start Time

Shift End Time

Planned Stop Time

Unplanned Stop Time

Total Production

Ideal Cycle Time(minutes)

Total Scrap

OEE

163%

Capacity

163%

Production

163%

Performance

163%

Quality

163%

Availability

163%

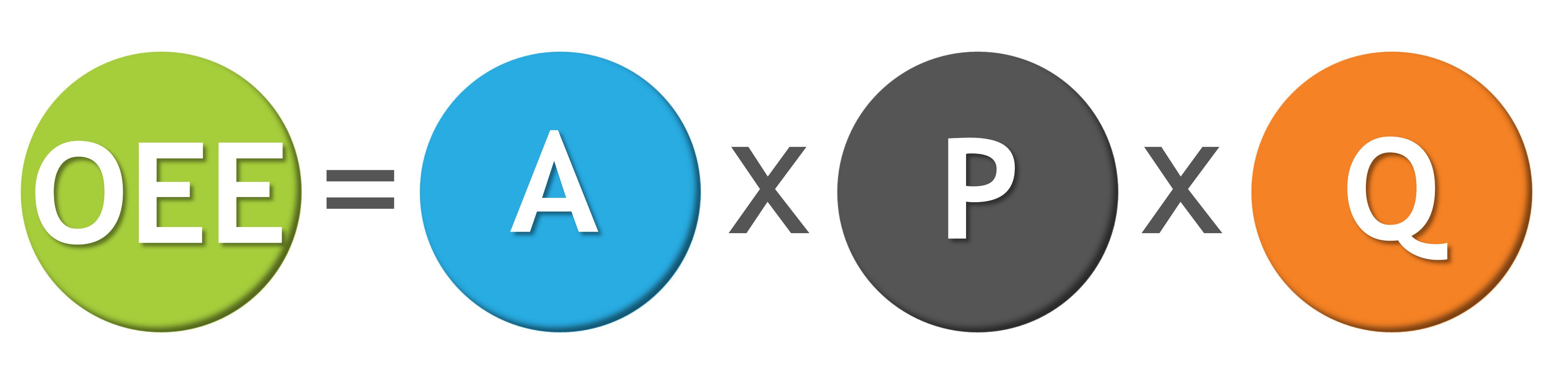

Let’s look at how we calculated your OEE above. The OEE formulas is:

Let’s break down each component of the OEE formula:

Availability

To calculate availability we first determine the duration of the shift in minutes.

Then subtract breaks, lunches and planned maintenance included in Planned Downtime.

Planned Production Time Formula:

Planned Production Time Calculation

Next calculate the operating time of the equipment. To do this subtract any unplanned downtime from the planned production time.

Operating Time Formula:

Operating Time Calculation:

Now we can calculate the availability percentage

Availability Formula:

Availability Calculation:

Performance

Performance is how the equipment is performing against its capacity. In this calculation we use the ideal cycle time and operating time to determine how many parts the machine can produce under ideal operating conditions. We then calculate the ratio of how many parts we actually produced vs the capacity.

Capacity Formula:

Capacity Calculation:

To calculate Performance we use the total parts produced, this includes any scrap or rejected parts.

Performance Formula:

Performance Calculation:

Quality

Quality is the ration of good parts versus total production.

Quality Formula:

Quality Calculation:

OEE Putting it Together

Now we take each of the three components and put them in the the formula above.