WHAT IS POKA-YOKE ?

Poka-Yoke is a concept introduced by Japanese management thinker Shiego Shingo. POKA is considered 'Carelessness and Thoughtfulness'; YOKE is considered 'Avoidance and Reduction', this concept can be interpreted as Insulation of Errors.

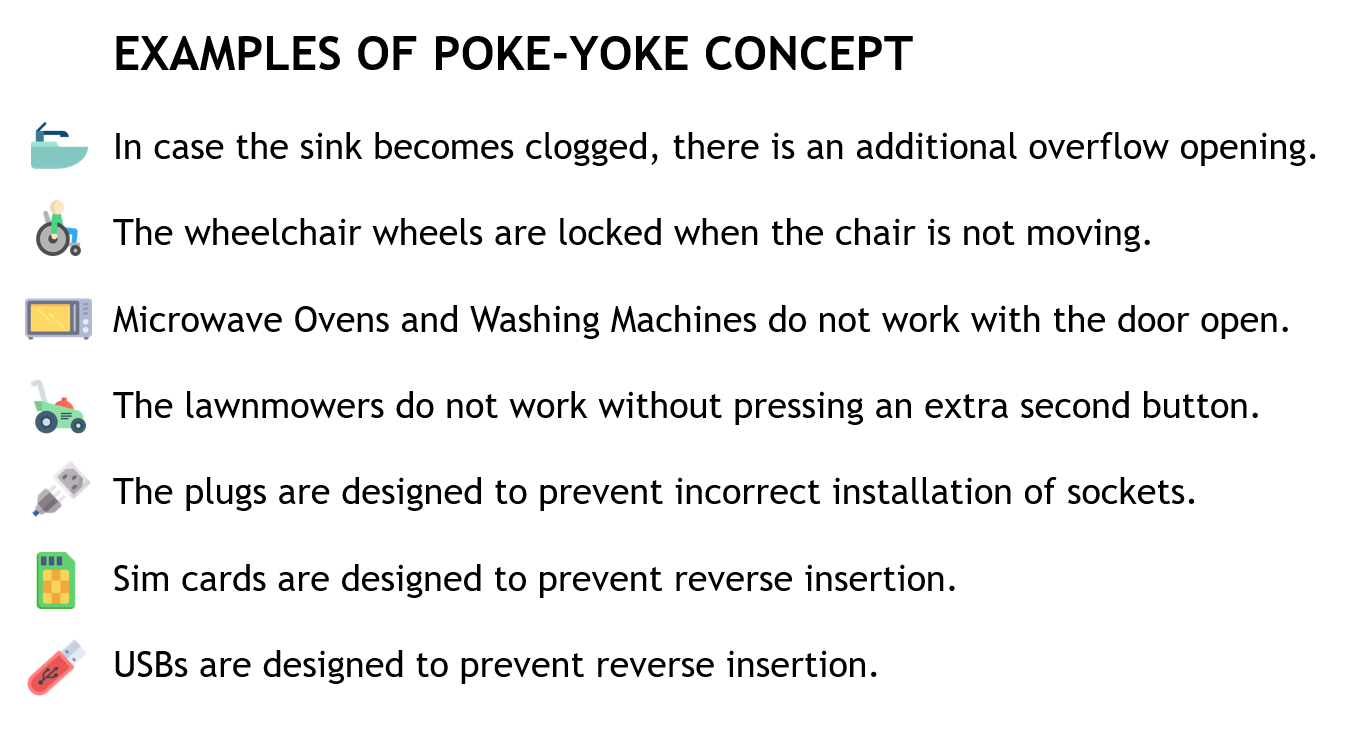

The main purpose of this system; is to prevent defective production in production facilities as a result of personnel carelessness or mistakes caused by wrong work. In our daily lives it is to prevent big mistakes with simple warnings / obstructions.

In the quality-control processes currently used in production facilities, defective products can be identified after certain problems are occured. It is impossible to control each product one by one, especially in mass production companies with a high number of production. Although samples taken periodically from production are flawless, defective products that are not noticed in these analyzes can reach the customer. A great deal of time and cost is spent on the detection and correction of these defective products. For this reason, it is very important to apply Poka-Yoke concept in enterprises and to prevent errors before they occur with simple applications.

Poka-Yoke (Insulation of Faults) method is more effective and simple than quality control / analysis methods thanks to its preventive structure.