WHAT IS SMED (SINGLE MINUTE EXCHANGE OF DIES)?

The SMED & MDS concept, like the Poka-Yoke concept, was introduced by Shigeo Shingo in Japan. The aim of this technique is to reduce the preparation times of the product changes during the production process to less than 10 minutes.

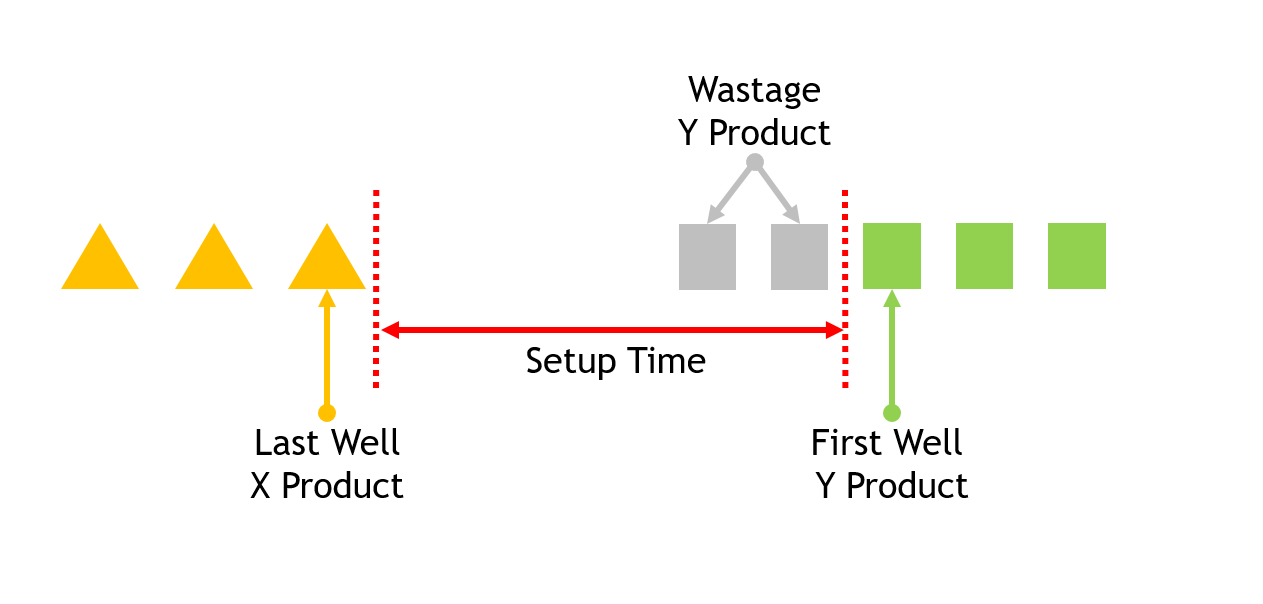

When applying this technique, we must first well understand the concept of “Preparation Time. Suppose that there are two different products named X and Y in our production process. Assume that the X and Y products are processed on the same machine and that the adjustment types and adjustment equipment used for both are different. The time between the last good (Quality Approved) X product coming out of the machine and the first good (Quality Approved) Y product produced after making the necessary adjustments is the preparation time and preparation activities are carried out for product transformation at this stage and at this stage preparatory activities are carried out for product transformation.

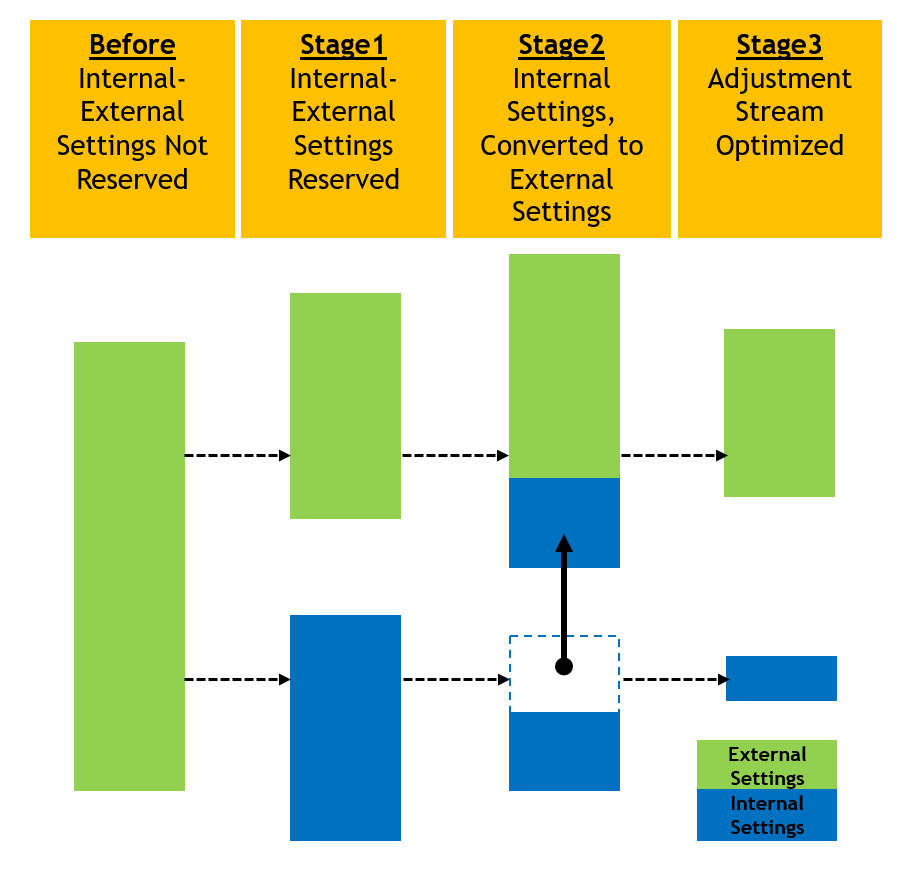

The most important step here is to separate the internal adjustment operations that can be performed only when the machine is off, from the internal adjustment operations that can be performed while the machine is running.

Stage 1: Almost all preparatory activities in a production line take place after the previous product is completed.However, when the previous product is produced, there are activities that can be carried out with the aim of preparing for the next product. In this context, in order to shorten the preparation period, these activities should be divided into In-Manufacturing and Non-Manufacturing. In this way, Non-manufacturing activities can be completed while the previous product is produced and the adjustment period can only be realized with In-Manufacturing activities. According to Shingo, only 30% - 50% improvement in preparation time can be achieved with this distinction.

Stage 2: In the second improvement stage, the activities carried out on the active machine are analyzed. This process focuses on the conversion of in-house settings to non-manufacturing settings and minimizes the internal setting time. If this phase is completed with the first phase, an improvement of up to 75% in preparation time can be achieved.

Final stage; monitoring and improvement process. In this process, observations are made on the internal and external settings and the points that can be improved are determined.

In the production facilities where SMED & MDS technique is applied;

- Production with smaller lots,

- Decreases scrap during preparation period,

- The cost of preparation labor is reduced,

- Production costs decrease,

- Increases productivity and machine utilization rates,

- Products are delivered in less time,

- The production system becomes more flexible.